Final Testing

The test of finished chip is to test the electrical characteristics and functional parameters of finished chip by using testing machine and sorting machine to distinguish good and defective products. In addition to routine testing, the company can also carry out targeted special testing for good products according to customer needs, to judge whether the chip can meet the special application scenarios of the product.

Test chip packaging shape includes SOP/TSSOP/SSOP/MSOP, QFN/DFN, LQFP, TQFP (thin plastic four-angle flat package), LGA, BGA, etc. The application fields of the chip mainly include 5G communication module, base station module, baseband module, satellite navigation, WIFI, power amplifier, RF filter, RF switch, etc.

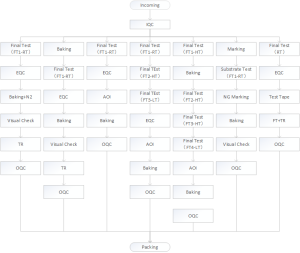

Final Testing Process:

The test R&D team has the following test engineering development capabilities:

1. Conducted feasibility assessment of product project development and software and hardware development of test scheme according to customer’s chip test scheme

2. Developed programs of various high-end test platforms in the industry (such as J750/V93K/NI), and realized software and hardware conversion among programs of each platform

3. With fingerprint identification class, touch class, SOC class, 32-bit MCU class, storage class, HD video conversion class, RF radio frequency class, industrial control class, intelligent wear class, the third generation of semiconductor and many other mass production test solutions

4. Multi-site development of the test program. FT 8 SITE and CP 256 SITE have been mass-produced

5. Design and manufacture Load Board and test fixture according to product requirements

6. Have the ability of Prober Card evaluation, design and manufacturing

7. Customize special mechanical equipment and related fixtures according to the test requirements of products

8. Develop MES management system, and upgrade and optimize MES system according to the needs of the company or customers